A Practical Project Management Playbook for Civil Engineers

Author: 360 Civil Engineering Editorial Team

Reviewed by: by Henry Petroski

Last updated: (29 January 2026)

Iconic infrastructure projects stay “iconic” because they survive changing loads, changing rules, and changing politics while still delivering public value. The common thread is not luck and not only engineering brilliance, but controlled delivery: locked scope, quantified risk, disciplined change control, strict quality gates, and clear stakeholder commitments. This article converts famous projects into practical project-management lessons you can apply on bridges, highways, tunnels, water works, and industrial civil packages.

You’ll also get copy-paste templates: an infrastructure risk register, a change-control workflow, an interface matrix, QA/QC hold points, and a commissioning checklist. If you adopt these tools as routine, you’ll reduce delays, avoid runaway variations, and deliver assets that remain maintainable long after handover.

1) Why Iconic Projects Are the Best Teachers

Iconic projects compress decades of engineering and management lessons into one outcome that everyone can inspect and judge.

They expose the real killers of schedule and budget: interfaces, assumptions, and uncontrolled changes, not just tough calculations.

They also reveal that “project completion” is not the same as “asset success” because operations and maintenance start the moment construction ends.

When a project becomes a public symbol, the tolerance for mistakes drops, and documentation, safety, and governance become just as critical as design. Studying these projects as case studies helps you recognize patterns early, even on smaller jobs with fewer zeros in the budget.

What to look for when you study any iconic job

- What was the scope baseline, and how often did it change?

- Where did uncertainty live (ground, wind, hydrology, utilities, politics)?

- Which interfaces were hardest (traffic, utilities, permits, operations)?

- What quality checks were “non-negotiable,” and what defects slipped?

- How was the asset maintained or retrofitted after opening?

1.1) How to Use This Playbook on Real Projects

Most articles about famous infrastructure stop at history; this playbook is meant to be used during delivery. The fastest win is to treat the tools in this post as a weekly routine—so risks, interfaces, and changes stay visible before they become claims. If you’re working on bridges, highways, utilities, tunnels, or water works, the same controls apply; only the constraints change. Use the case studies as “pattern recognition,” then apply the templates as your day-to-day operating system. The goal is simple: fewer surprises, cleaner approvals, and a smoother handover.

- Design phase: Start the Risk Register + Decision Log at 30% design; update at 60% and IFC.

- Procurement phase: Add “lead-time risks” and lock alternates; start a Change Log the moment scope is baselined.

- Construction phase: Review Risk Register + Interface Matrix + Change Log weekly; enforce QA/QC Hold Points before work is covered.

- Handover phase: Run the Commissioning & Handover Checklist like a mini-project with dates, owners, and witnessed tests.

1.2) What to look for when you study any iconic job

When you read about a landmark project, the most useful lessons are rarely in the glossy overview. The real story lives in baselines, approvals, interface conflicts, and the assumptions that were later proved wrong. If you train yourself to “read” a project like a delivery system, you’ll start spotting risk early on your own jobs. This checklist is designed to keep you focused on what actually moves cost and schedule in civil works. Use it before design freezes and again during construction when changes start piling up.

2) What Makes a Project Truly “Iconic” in Practice

A project becomes iconic when it keeps performing as real conditions change, not when it looks good on opening day.

Traffic grows, hazards evolve, standards update, and environmental exposure keeps attacking materials, joints, and protective systems.

The delivery team matters because governance and documentation determine how fast the asset can be upgraded without chaos and claims. The design matters because maintainability and inspection access decide whether the owner can keep the asset healthy at a predictable cost. Iconic outcomes usually come from teams that planned for adaptation, not teams that assumed the future would stay friendly.

Iconic traits you can measure on your own projects

- Durability under exposure: corrosion, fatigue, freeze-thaw, abrasion, scouring.

- Maintainability: access, drainage, replaceable components, inspection points.

- Adaptability: widening, retrofits, operational changes, sensor upgrades.

- Clear approvals: decision logs, sign-offs, traceable changes.

- Public value: safety, mobility, water security, or economic impact.

3) Case Studies and the Lessons They Teach

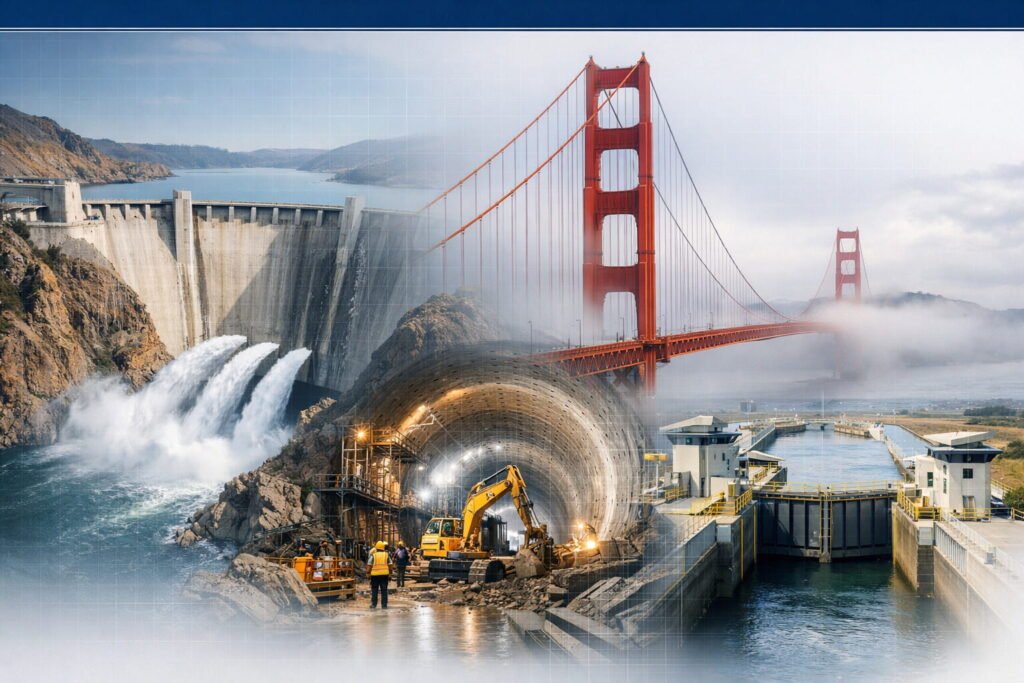

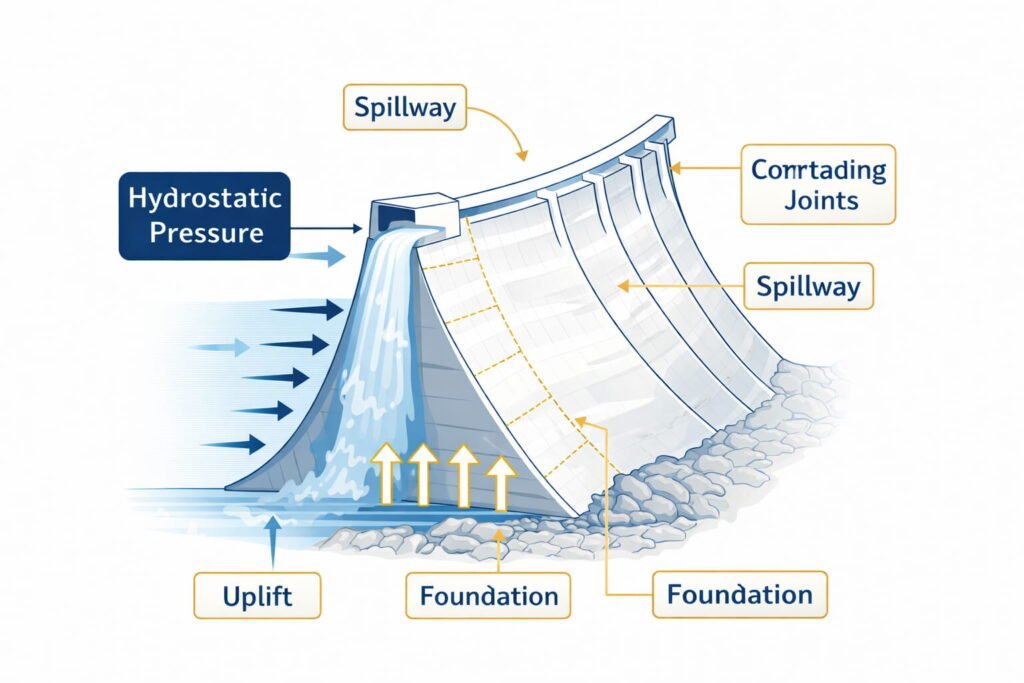

3.1 Hoover Dam — Delivery Under Extreme Constraints

Hoover Dam shows what happens when schedule, logistics, and safety must work together under extreme heat and high-stakes public attention.

The engineering is famous, but the repeatable lesson is the delivery system: sequencing, curing controls, material movement, and worker protection.

This type of job proves that site constraints are not “issues,” they are scope, and they must be written into methods and schedules early.

It also reminds civil teams that water infrastructure is operationally sensitive, so handover readiness matters as much as concrete placement.

If you build any high-volume concrete structure, treat thermal control, quality records, and commissioning as first-class deliverables.

Lessons you can reuse on real projects

- Build a logistics plan that includes routes, staging, storage, and bottlenecks.

- Put safety audits into the schedule as milestones, not as optional activity.

- Treat concrete temperature, curing, and testing as a controlled process with logs.

- Plan commissioning procedures, training, and emergency response before handover.

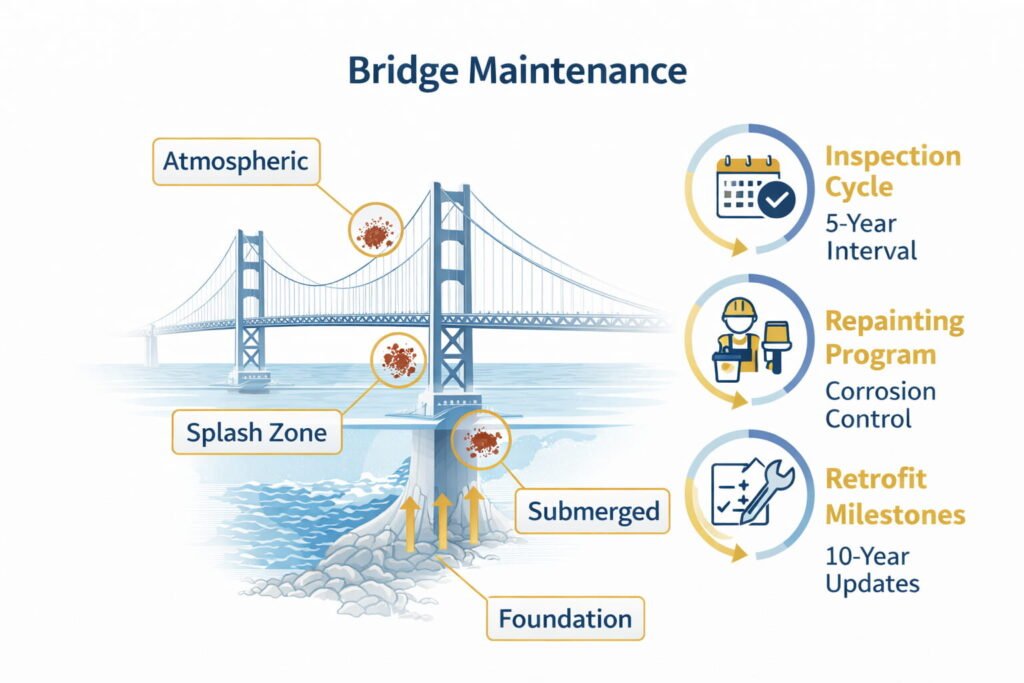

3.2 Golden Gate Bridge — Environment, Fatigue, and Never-Ending Maintenance

Golden Gate Bridge is a masterclass in how environment turns into lifecycle cost, especially with fog, salt exposure, wind, and continuous traffic.

A suspension bridge is not “done” at opening because corrosion management and inspection regimes become permanent work programs.

This case highlights a truth many project teams ignore: saving cost in maintainability often creates decades of predictable spending later.

It also shows why retrofits happen on great assets because hazards, standards, and monitoring tools evolve over time.

If your project will live in aggressive exposure, your delivery plan must include coatings strategy, access, and inspection records from day one.

Lessons you can reuse on real projects

- Add maintainability requirements to design: access, drainage, replaceable joints.

- Define coating systems and inspection frequency as part of acceptance criteria.

- Budget lifecycle costs early so the owner can fund maintenance without crisis.

- Plan retrofit pathways with triggers, not only with “future study” notes.

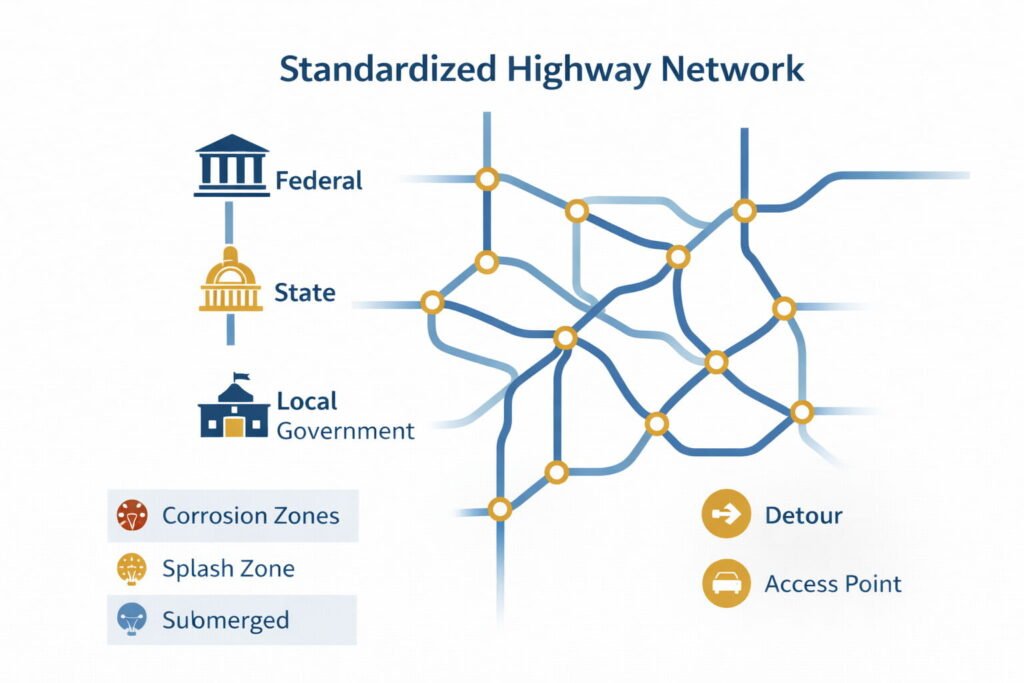

3.3 The U.S. Interstate System — Standardization, Governance, and Social Risk

The Interstate program shows how standardization can reduce delivery risk across huge geographies and multiple agencies.

It also shows that right-of-way, community impact, and political acceptance are not side topics because they directly affect schedule and scope.

In highway work, interfaces multiply fast: utilities, traffic staging, environmental conditions, and local business access all compete for priority.

This kind of work rewards teams that build transparent governance and communicate staging and impacts early and consistently.

If your road project faces public disruption, stakeholder planning becomes schedule protection, not public relations.

Lessons you can reuse on real projects

- Put right-of-way, utilities, and permits on the critical path early.

- Standardize specs and details to reduce contractor interpretation and defects.

- Treat traffic management and detours as safety deliverables with inspections.

- Maintain an impact log: what changed, who it affects, and mitigations.

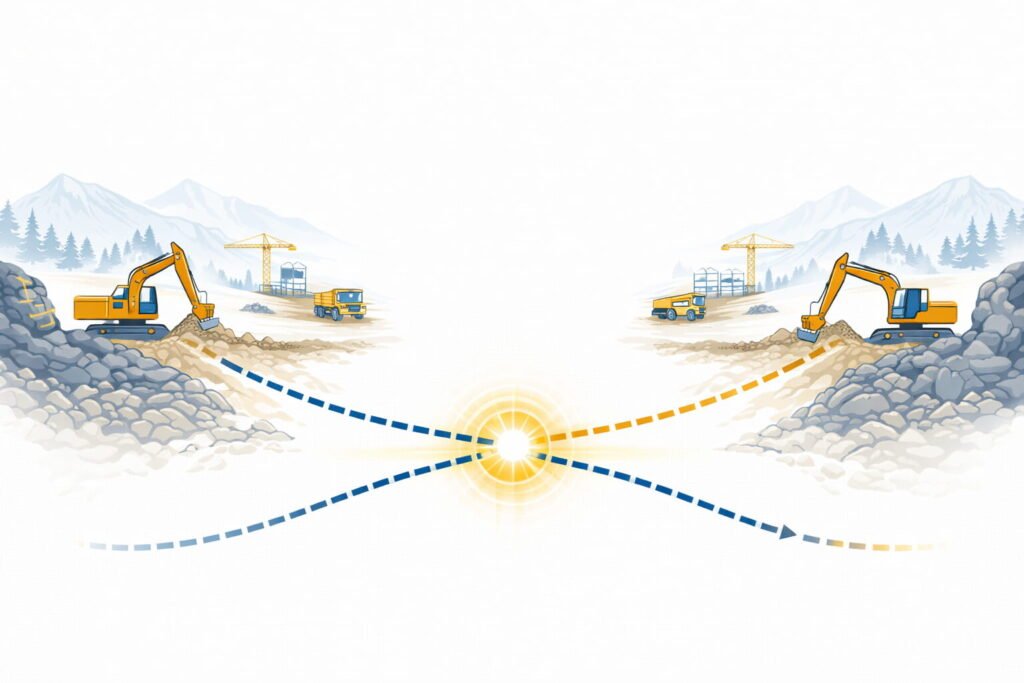

3.4 Transcontinental Railroad — Interface Milestones and Logistics Reality

This project demonstrates the power and danger of interface milestones when multiple teams build toward a single connection point.

Terrain, weather, supply constraints, and workforce limits can break optimistic schedules unless logistics is planned like engineering.

It also reminds modern teams that workforce welfare and safety are delivery risks that can stop work and damage trust quickly.

From a PM lens, the most repeatable lesson is coordination discipline: tolerances, alignment, handoff dates, and approvals must be explicit.

If you manage interfaces loosely, you will buy rework later at the worst possible time.

Lessons you can reuse on real projects

- Define interface milestones early and assign one owner per interface.

- Use a logistics risk register: access, lead times, storage, seasonal windows.

- Track procurement as a system with alternates and triggers.

- Put safety and welfare checks into the schedule, not only into policies.

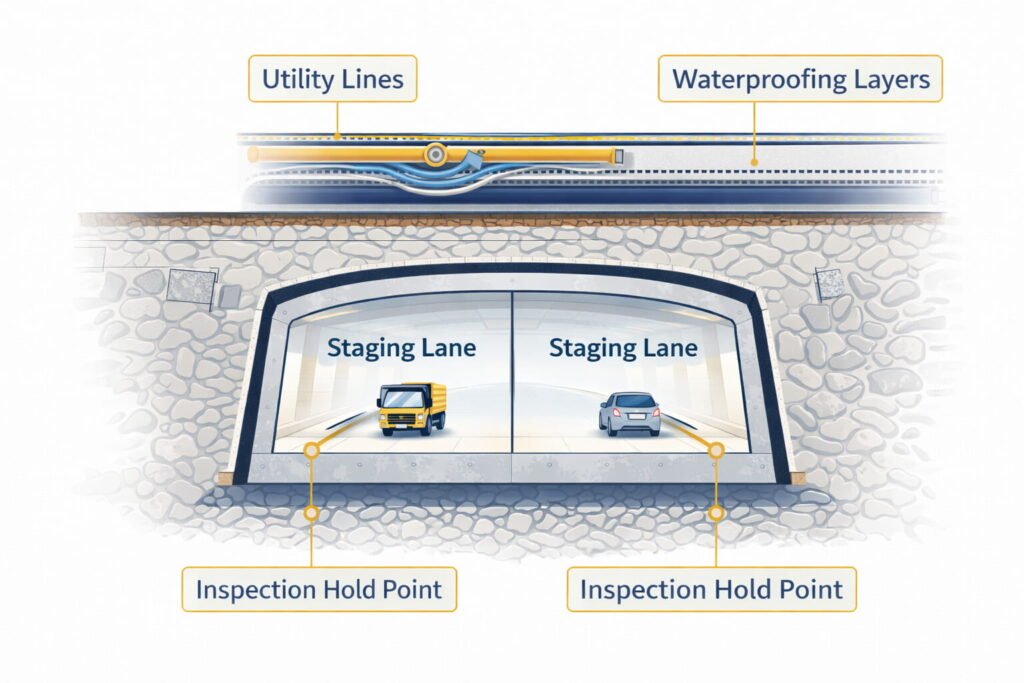

3.5 The Big Dig — Change Control, Urban Interfaces, and Quality You Can’t “Fix Later”

Urban tunneling and deep corridor work magnify every weakness in documentation and change control.

Small scope changes can cascade into major cost and schedule impacts because utilities, staging, groundwater, and safety systems are tightly coupled.

This case teaches that quality must be stoppable: defects in waterproofing, reinforcement, and critical systems become inaccessible after closure.

It also proves that interface management is not a meeting; it is a living matrix with owners, dates, and constraints.

If you do any underground work, you need strict hold points, complete photo logs, and disciplined approvals before work is concealed.

Lessons you can reuse on real projects

- Use a Change Control Board with thresholds and documented decisions.

- Require impact analysis for every change: cost, schedule, risk, safety, permits.

- Enforce QA/QC hold points before closing or covering critical work.

- Maintain an interface matrix for utilities, agencies, traffic, and emergency access.

3.6 Panama Canal Expansion — Program Management and Operational Readiness

Expanding a live global system teaches program-level coordination: multiple packages, environmental constraints, and operational continuity.

It highlights that commissioning is not a closing task because the system must perform safely under real traffic and real emergency conditions.

It also demonstrates how a resource constraint like water can become a dominant long-term operational risk.

From a PM standpoint, the repeatable lesson is to treat operational readiness as deliverables: procedures, training, drills, and monitoring.

If your project connects to operations, your acceptance criteria must include readiness, not only construction completion.

Lessons you can reuse on real projects

- Use a program risk register that includes operations and resource constraints.

- Track readiness deliverables: SOPs, training, maintenance plans, emergency actions.

- Verify performance with witnessed tests and documented acceptance.

- Build monitoring and instrumentation into the handover package.

4) Tools You Can Copy Into Your Next Project File

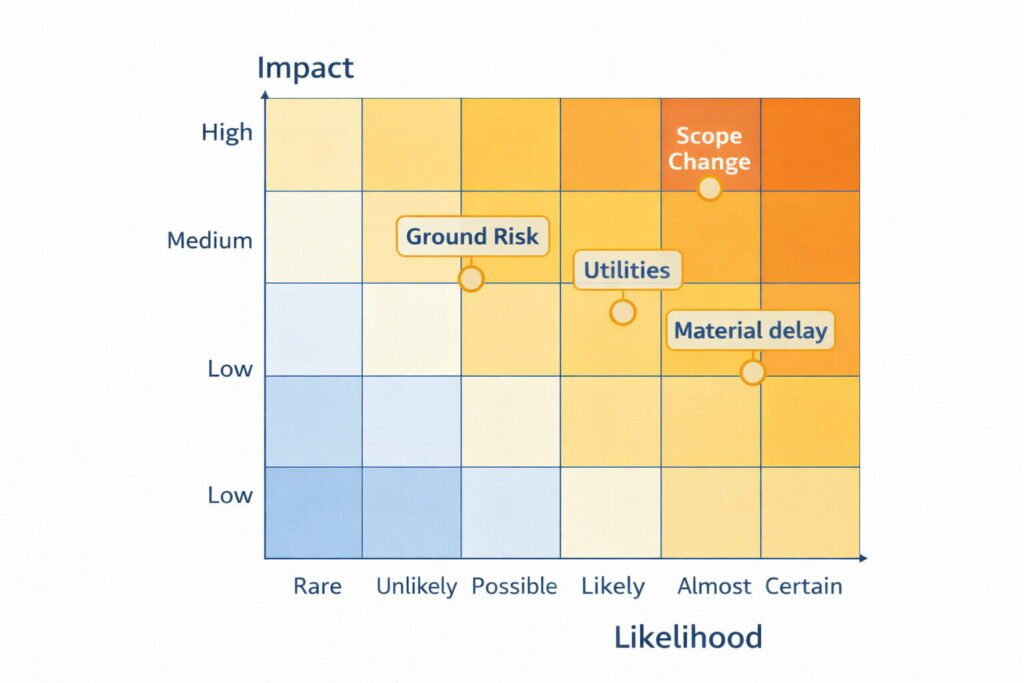

4.1 Infrastructure Risk Register

A risk register is only useful when it is updated on a calendar, not when it is created once and forgotten.

The purpose is not to predict everything, but to force ownership, triggers, and actions before the risk becomes a claim.

Write triggers in plain language so site staff can recognize early warning signs without guessing.

Update it at design gates and at construction milestones, then review it weekly in coordination meetings.

If a risk has no owner, assume it will become a problem with no defense.

Template

| ID | Risk | Phase | Probability (1–5) | Impact (1–5) | Score | Trigger (what you’ll see) | Owner | Mitigation (before) | Contingency (if it happens) |

|---|---|---|---|---|---|---|---|---|---|

| R-01 | Unexpected ground conditions | Construction | 4 | 5 | 20 | Bore logs conflict with excavation | Geotech Lead | Extra investigations, flexible methods | Time/cost allowance + redesign |

| R-02 | Late scope change | Design | 3 | 4 | 12 | New requirement after baseline | PM | Change gate + decision log | Re-scope or approve variation |

| R-03 | Material lead-time slip | Procurement | 3 | 3 | 9 | Supplier date moves >2 weeks | Procurement | Dual source + early orders | Resequence + approved alternates |

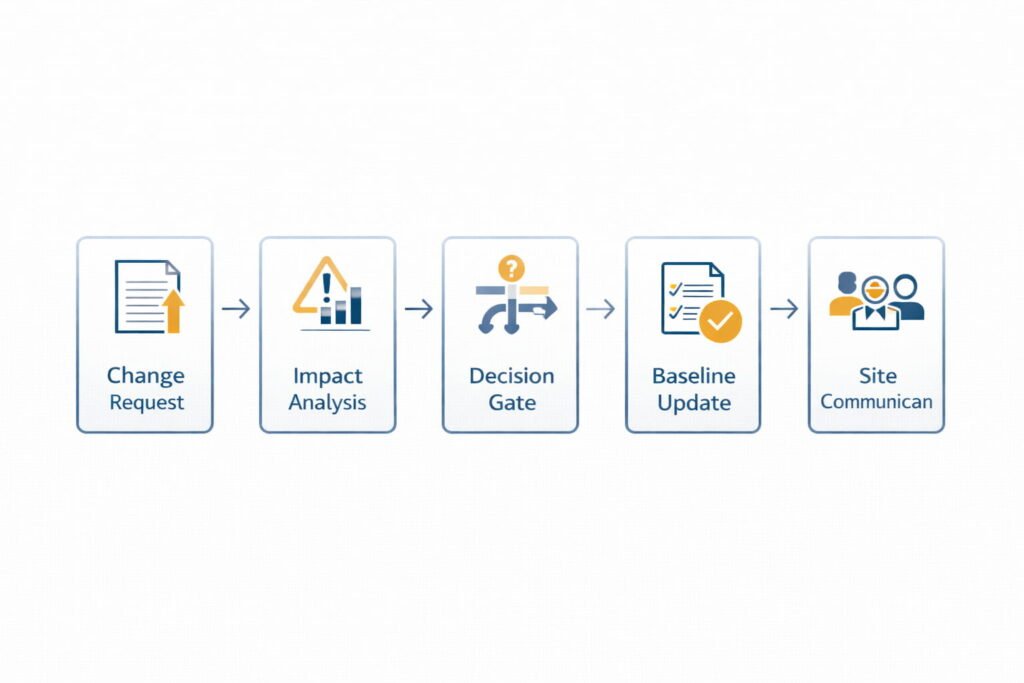

4.2 Change Control Workflow (One Gate for Every Change)

Most overruns happen through dozens of small changes that never got priced and scheduled properly.

A simple workflow protects everyone by forcing clarity: what changed, why it changed, and what it costs in time and money.

It also prevents field teams from drifting away from the approved baseline when pressure rises.

The goal is not bureaucracy, but truth: every change has an impact, and the project deserves to see it.

If your workflow is inconsistent, your schedule becomes a guess and your budget becomes a story.

Workflow

- Log the change request with date, requestor, and description.

- Complete impact analysis: scope, cost, schedule, risk, safety, quality, permits.

- Record the decision with reasons: approve, reject, or defer.

- Update baselines: drawings, quantities, schedule, method statements.

- Communicate to all interfaces and field teams with one source of truth.

Change Log (Track Every Change in One Place)

A workflow is only as good as its record. The change log prevents “invisible” scope creep by forcing every change into a numbered trail with status, owner, and impact. It also speeds up claims avoidance because you can show what was approved and what was not. Keep it updated weekly and review it with the same discipline as your schedule. If a change is not in this log, treat it as not approved.

| CR # | Date Raised | Change Summary | Cost Impact | Schedule Impact | Status (Proposed/Approved/Rejected) | Owner | Notes |

|---|---|---|---|---|---|---|---|

| CR-01 | (date) | (summary) | (±$ / TBD) | (±days / TBD) | (status) | (name) | (notes) |

4.2.1 Decision Log (Prevents “We Never Agreed To That” Problems)

Most disputes are not caused by bad intentions—they happen because decisions are made in meetings, then forgotten or reinterpreted later. A decision log creates one source of truth: what was decided, why, which options were considered, and who approved it. It also makes future changes easier, because you can see the original assumptions and constraints. On complex jobs, this is one of the highest-ROI documents you can maintain. Update it whenever scope, method, materials, access, or compliance requirements shift.

Decision Log Template

| Decision ID | Date | Decision (What was approved?) | Reason (Why?) | Options Considered | Impact (Cost/Schedule/Risk) | Approved By | Notes/Links |

|---|---|---|---|---|---|---|---|

| D-01 | (date) | (example: shift staging method) | (reason) | (A/B/C) | (summary) | (name/role) | (ref) |

| D-02 | (date) | (example: material alternate) | (reason) | (A/B/C) | (summary) | (name/role) | (ref) |

4.3 Interface Matrix (Stop “Coordination” From Becoming Chaos)

Interfaces are where good plans go to die: utilities, traffic staging, agency approvals, operations needs, and contractor boundaries collide.

An interface matrix turns vague coordination into accountable actions with owners and dates.

It also reduces disputes because responsibilities are documented and visible to everyone.

Update it whenever staging changes, when design packages are released, and when new constraints appear.

If you don’t manage interfaces actively, you will manage them reactively under stress.

Template

| Interface | Parties | What can go wrong | Required action | Owner | Due date | Status |

|---|---|---|---|---|---|---|

| Utility relocation | Contractor + utility owner | Outage risk | Approved window + method | Utilities Lead | (date) | (status) |

| Traffic staging | Contractor + agency | Unsafe detours | TMP approval + inspection | Traffic Lead | (date) | (status) |

| Commissioning | Contractor + operations | Handover failure | SOP + training + tests | Commissioning Lead | (date) | (status) |

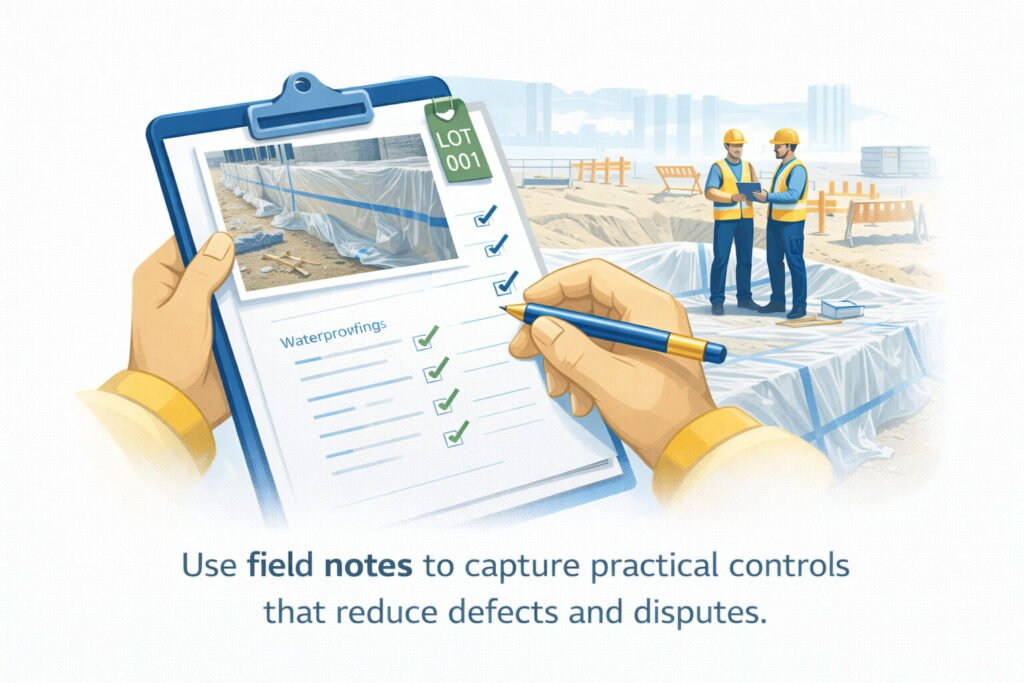

4.4 QA/QC Hold Points (Quality That Can Be Enforced)

Quality control fails when defects get hidden behind concrete, asphalt, backfill, or finishes.

Hold points stop wrong work before it becomes impossible or expensive to correct.

They also protect the project legally by creating a traceable acceptance record.

The best hold points are measurable, documented, and tied to specific activities on the schedule.

If you cannot “stop” work for quality, quality is not under control.

Hold-point checklist

- Materials certification verified with traceability records.

- Pre-install inspection passed for reinforcement, embeds, and clear cover.

- Waterproofing inspected with photo log and signed acceptance.

- Concrete testing plan executed and filed (slump, cylinders, temperature).

- As-builts updated weekly and cross-checked with field conditions.

Field Note (From Site Reality)

In cut-and-cover and underground work, waterproofing defects are among the most expensive to fix because the problem often appears after the structure is covered and traffic is restored. The simplest control is procedural: treat waterproofing as a hold point with a photo log, batch/lot traceability, and signed inspection acceptance before any cover/backfill is allowed. On projects where this was enforced, rework dropped sharply and close-out went faster because the evidence trail already existed. If your site team only “checks” waterproofing informally, you’re essentially betting the schedule on luck.

4.5 Commissioning and Handover Checklist (Make “Operational” the Real Finish Line)

Handover is where many civil projects quietly fail because teams treat it as paperwork after the build.

A strong commissioning plan defines how the asset will operate, how it will be maintained, and how failures will be handled.

It also clarifies training, spares, documentation, and performance testing before the owner takes responsibility.

Commissioning should start early so procedures and access needs can influence design and construction decisions.

If you wait until the end, you will discover missing documentation at the worst moment.

Commissioning checklist

- Operating procedures drafted and reviewed with operations staff.

- Training completed with attendance records and competency sign-off.

- Performance tests witnessed and documented against acceptance criteria.

- Maintenance schedule and spare parts list handed over and verified.

- Emergency response plan and contact chain confirmed and rehearsed.

5) Writing and Structuring This Topic for Search and Real Readers

Readers land on this topic because they want practical lessons, not a museum tour of famous structures.

That means every section must answer a decision question: what to do, what to avoid, and how to prove it worked.

Short summaries help scanning, while templates help implementation, and that combination keeps people on the page.

Case studies should be written as mechanisms: trigger → mistake → consequence → fix, rather than as hype.

When you update the post with new tools or local field notes, the article stays useful and trustworthy over time.

Before you publish, do these finishing steps

- Replace reviewer placeholder with a real person and credentials.

- Add one short local “field note” paragraph from your experience (site constraint, safety lesson, QA story).

- Add internal links from your related PM/estimation/QA articles (no keyword-stuffed anchors).

- Add 2–3 supporting internal links out of this post to your own calculators or templates.

Final Takeaways

Iconic infrastructure is not built by motivation, it is built by disciplined decisions repeated for months and years.

The projects above prove that scope control, risk ownership, interface management, and enforceable quality gates are the real difference between stable assets and endless disputes.

If you adopt the templates in this article as a routine, you will catch problems earlier and defend decisions with evidence.

Design choices become stronger when maintainability and commissioning are treated as real requirements, not as end-of-project tasks.

Use this playbook as a living system: refine it after each project, and your next delivery will be calmer than your last.

Top 10 lessons in one list

- Freeze scope baseline early and keep a decision log.

- Quantify risks, assign owners, and track triggers weekly.

- Use one formal change gate for every scope or spec change.

- Manage interfaces with an owner, date, and status—not by memory.

- Make QA/QC stoppable with hold points and acceptance records.

- Plan logistics like engineering: routes, staging, bottlenecks, alternates.

- Budget lifecycle needs and design for inspection and maintenance access.

- Treat commissioning as deliverables: SOPs, training, witnessed tests.

- Keep as-builts alive weekly so handover is smooth and defensible.

- Communicate impacts early and consistently to protect schedule and trust.

FAQs

FAQs: Iconic Infrastructure & Project Management

These frequently asked questions cover risk management, scope control, QA/QC, interfaces, commissioning, and lifecycle planning for major civil engineering projects.

1 What makes an infrastructure project “iconic” in civil engineering and asset management?

2 Why do megaprojects and large infrastructure projects commonly experience cost overruns and schedule delays?

3 What is the best risk management approach for civil engineering projects (risk register vs risk matrix)?

4 How do you control scope creep in infrastructure delivery without slowing the project?

5 What are “interfaces” in construction management, and why do they cause disputes?

6 How do QA/QC hold points reduce defects in tunnels, bridges, and waterproofing systems?

7 What is commissioning in civil infrastructure, and what should a handover checklist include?

8 How should engineers plan for corrosion, fatigue, and maintenance on coastal bridges and exposed structures?

9 What’s the difference between a Decision Log, Change Log, and Risk Register in project controls?

10 How can this playbook help with Google Discover visibility and international search intent?

Source Notes

Hoover Dam public records (U.S. water infrastructure archives)

Golden Gate Bridge public history and key dates (bridge district archives)

U.S. interstate program archives (federal highway records)

Big Dig public project information (Massachusetts public records)

Panama Canal expansion public communications (canal authority records)